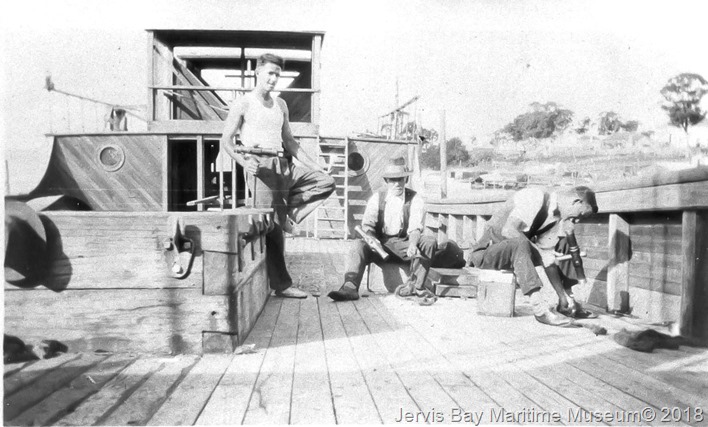

Another fascinating image from 1933.

Workmen on board the John Bolton in the process of water proofing the deck timbers. Tapered gaps in the deck planks would be filled with fibre, cords, and pitch in a process called caulking. The fibre was usually Oakum, (hemp fiber soaked in tar) derived from Jute, the pitch was usually tar. The process was highly skilled, not enough fill and the ship would let in water, to much and the planks could split apart. Wooden caulking mallet was used to carefully tap the fibre into the groves with caulking irons, caulking irons are chisel-like tools with flared blades they varied in shape, they could be sharp, blunt or made with grooves known as creases, each had a specific purpose. The steady tapping from the wooden mallets could be heard all over Huskisson and was refered to as "singing".

Examples of the timber mallets and irons used in the photograph can be found on display at the museum, as well as many other tools used in building ships.

The area the tools are displayed in at the museum was built in the same manner used to build wooden ships by Alf Setree the last of the wooden boat builders in Huskisson.

I have covered the launch and followed the workings of the John Bolton in a previous post, a fascinating tale, well worth a read. Continue reading.

13 August 2018

John Bolton

Subscribe to:

Post Comments

(

Atom

)

No comments :

Post a Comment